IMOCA becomes the first class in sailing to impose an impact reduction rule on boat construction

An impact reduction rule limiting harmful emissions in boat construction has been the major goal of the sustainability work that IMOCA has been conducting over the last four years and now it is being implemented.

At this week’s Annual General Meeting of the Class in Lorient in Brittany, the skippers and teams formally endorsed a new regime that will require all new boat builds in IMOCA undertaken between 2025 and 2028 to reduce harmful emissions by 15%.

This is something that no other class in the sport of sailing has achieved and represents a historic step forward in bringing IMOCA activity, and the industry that supports it, in line with public sentiment on the crisis facing our planet.

Antoine Mermod, President of the IMOCA Class, said an impact reduction rule has now become a reality after several years of research and consultations with skippers, teams, naval architects, boatyards, suppliers and commercial partners.

“With an impact reduction rule now in place we are pushing the teams when they are building a new boat to choose ways that minimise the impact of that process,” said Mermod.

“This will change the way we operate, but also change the maritime industry that supports us who are very happy to follow us. Even if it is not very spectacular to say that this is what we are doing,”he added, “it is a very, very important moment and a huge move for the future of our industry.”

© Marin LE ROUX - polaRYSE

© Marin LE ROUX - polaRYSE

Damien Seguin, the Groupe APICIL skipper, said the adoption of the rule is a positive step not only for IMOCA but offshore racing as whole and potentially the entire nautical industry that sends a clear signal to everyone. “I think it’s great and courageous that this has been done and voted on,”he said.

“This marks a turning point in the history of the Class, as it will likely influence architectural choices throughout the decision-making chain, from the skippers to the architects, design teams and shipyards,” added Seguin.“The aim is to reduce our environmental impact, particularly by limiting the use of carbon in boat construction and related components.”

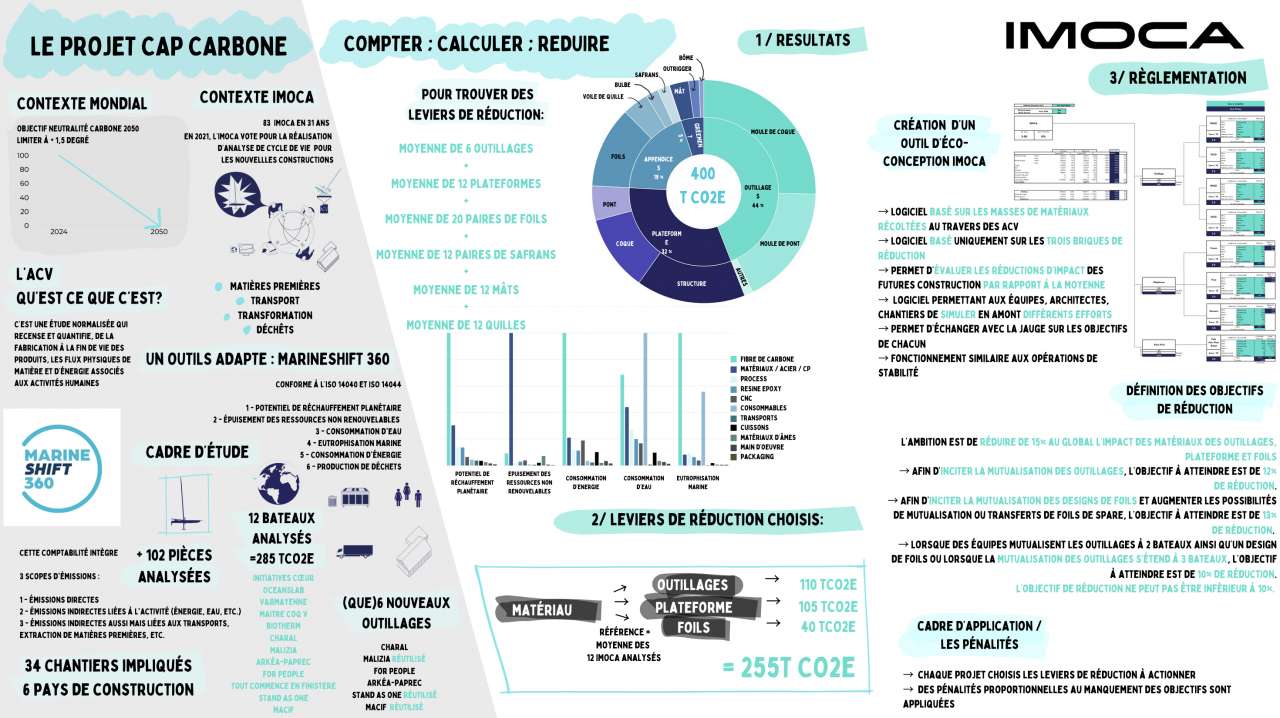

The long road to the imposition of an impact reduction rule has seen the Class use Life Cycle Assessment, or LCAs, on all recent new boat builds to understand the full extent of their environmental impact. The next step was to identify the key areas where emissions could be reduced and then develop a piece of software, dubbed the “Eco-Conception Tool,” to help designers and boat-builders understand how they can make reductions in emissions to hit the 15% reduction target.

© Marin LE ROUX - polaRYSE

© Marin LE ROUX - polaRYSE

“From all of our LCA analysis, we identified three hotspots where reductions could be made – the boat moulds, the platforms (hull, deck and internal structure), and the foils,” said Imogen Dinham-Price, Sustainability co-manager at IMOCA.

“We saw that the moulds accounted for 44% of total emissions, foils came out at 13% with the platform at 32%. The Eco-Conception Tool allows designers and teams to play around with different scenarios, so they can reduce their impact by determining the quality of different materials they use in each of those three areas.”

In all new builds from now on we can expect to see teams using less carbon-fibre – and particularly intermediate-modulus carbon-fibre which is emission-intensive – in hull moulds, in deck moulds, deck structures and foils. Instead alternatives will be used such as glass-fibre or standard modulus carbon.

Noémie Provost, Technical and LCA Manager at IMOCA, says she does not believe there will be a performance penalty for new boats hitting their emission targets under the rule.“We think that architects will find new boat and foil shapes to continue to be competitive. They have a lot of software to analyse hull and foil shapes and they should be able to find improved performance as before,”she said.

Both Provost and Dinham-Price who, along with Samuel Valverde, have led IMOCA’s work on the new restrictions, believe the teams will achieve the reductions as set out in the rule. They say most of them recognise it is a response to an issue which the Class must address. “We have teams that say ‘yes, we need to go in this direction if we want our sport to continue through this transition to less impactful boat construction,’” Provost summarised.

The Class says the new regime should cut costs because there will be less use of the most expensive materials. However, if a boat does not conform to the restrictions as set out in the rule, penalties will be applied that could, for example, restrict the numbers of foils a boat can use or reduce its allocation of new sails.

© Marin LE ROUX - polaRYSE

© Marin LE ROUX - polaRYSE

In the long run the Class’s ambition is to build on this first step after 2028. “The goal is to continue to reduce emissions,”said Provost. “Maybe 15% more between 2028 and 2032. And maybe as well, by continuing to use the LCAs, we will be able to determine if this rule works well or not because we will be able to assess the next builds and understand their impact, so we will have some new data to set new objectives.”

Dinham-Price says IMOCA is leading an industry that “is changing and going in the right direction.”She says the Class is taking the initiative in an area of the economy that is not controlled by government-set targets.“We are setting our own agenda,” she said. “That is producing an enormous amount of cooperation and understanding of the global situation within our industry.

“And it won’t just be the Class that benefits,”she added, “because if we have the possibility of changing and adapting one small process – for example, adding flax to our moulds or having foils built with less waste – these changes will reflect a whole industry involvement behind them.”

© Marin LE ROUX - polaRYSE

© Marin LE ROUX - polaRYSE

Seguin said implementing the impact reduction regime will be challenging, but he believes the Class has the resources to ensure it will be a success.“Within the Class, there are individuals who will help understand this rule thoroughly, because it’s not as simple as it seems to grasp all the different reduction percentages we want to achieve and how it fits into projects seamlessly,” he said.

“The Class supports teams and the thought process to calibrate all of this. I’m convinced that we have a strong and innovative tool at our disposal, and now it’s just a matter of putting it into practice. I have little doubt that in the future, other classes will closely monitor what we do and align with this model,” he added.

Ed Gorman

Teams info

Damage on Holcim-PRB

Whilst sailing in 5th position in The Transat CIC fleet, Nicolas Lunven, skipper of the IMOCA Holcim-PRB, informed his shore team at 10h HF this Wednesday morning that his bowsprit had broken. The damage occurred during …

•••